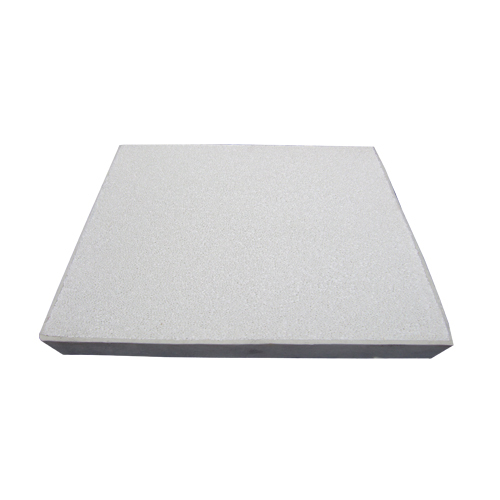

Alumina Ceramic Foam Filter - Molten Aluminum Filter

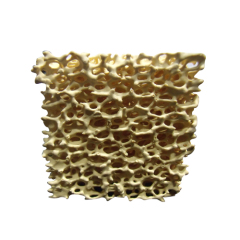

Our ceramic foam filter use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

Function:

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Alumina ceramic foam filters are different from aperture specifications from 20 to 50ppi, with different sizes and shapes.

Chemial composition: Al2O3 is more than 85%, SiO2 is less than 15%

Form A--alumina ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2 | Pressure resistence intensity in normal temperature N/cm2 | Pressure resistence intensity in high temperature N/cm2 | Refractory temperature | Air discharging capability cm3/g | Porosity % |

| 15-100 | 20-50 | 0.45-0.55 | ≥38 | ≥80 | ≥45 | ≥1200 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of alumina ceramic foam filter

Specification mm | Area M2 | Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

| 7’’X7’’X2’’ | 0.0213 | 57.00 | 25-45 | 4.2 |

| 9’’X9’’X2’’ | 0.0387 | 118.00 | 35-102 | 6.9 |

| 12’’X12’’X2’’ | 0.0745 | 198.00 | 90-165 | 13.8 |

| 15’’X15’’X2’’ | 0.122 | 325.80 | 130-265 | 23.2 |

| 17’’X17’’X2’’ | 0.160 | 427.20 | 210-350 | 34.5 |

| 20’’X20’’X2’’ | 0.227 | 606.60 | 280-465 | 43.7 |

| 23’’X23’’X2’’ | 0.341 | 772.20 | 370-540 | 57.3 |

The size is changeable according your actual requirements.

working temperature is about 1200 Degree Celsius

the size is changeable ac